CELO, global industrial fasteners and screw manufacturer

POWERLOK® II™ screws

When to choose POWERLOK® II™ screw?

TRILOBULAR® POWERLOK® II™ screws are recommended to solve loosening problems in tapped holes, specially in the assembly of components under severe vibration conditions and expansion/contraction cycles.

With excellent resistance to vibration-induced loosening, POWERLOK® II™ screw eliminates the need for additional locking elements and complies with IFI 524 regulations for screw loosening resistance. The screws can reach Property Class 10.9 mechanical properties, offering high-strength levels suitable for a wide range of demanding applications.

How does it work?

TRILOBULAR® POWERLOK® II™ screw for metal is a unique locking concept solution for tapped holes:

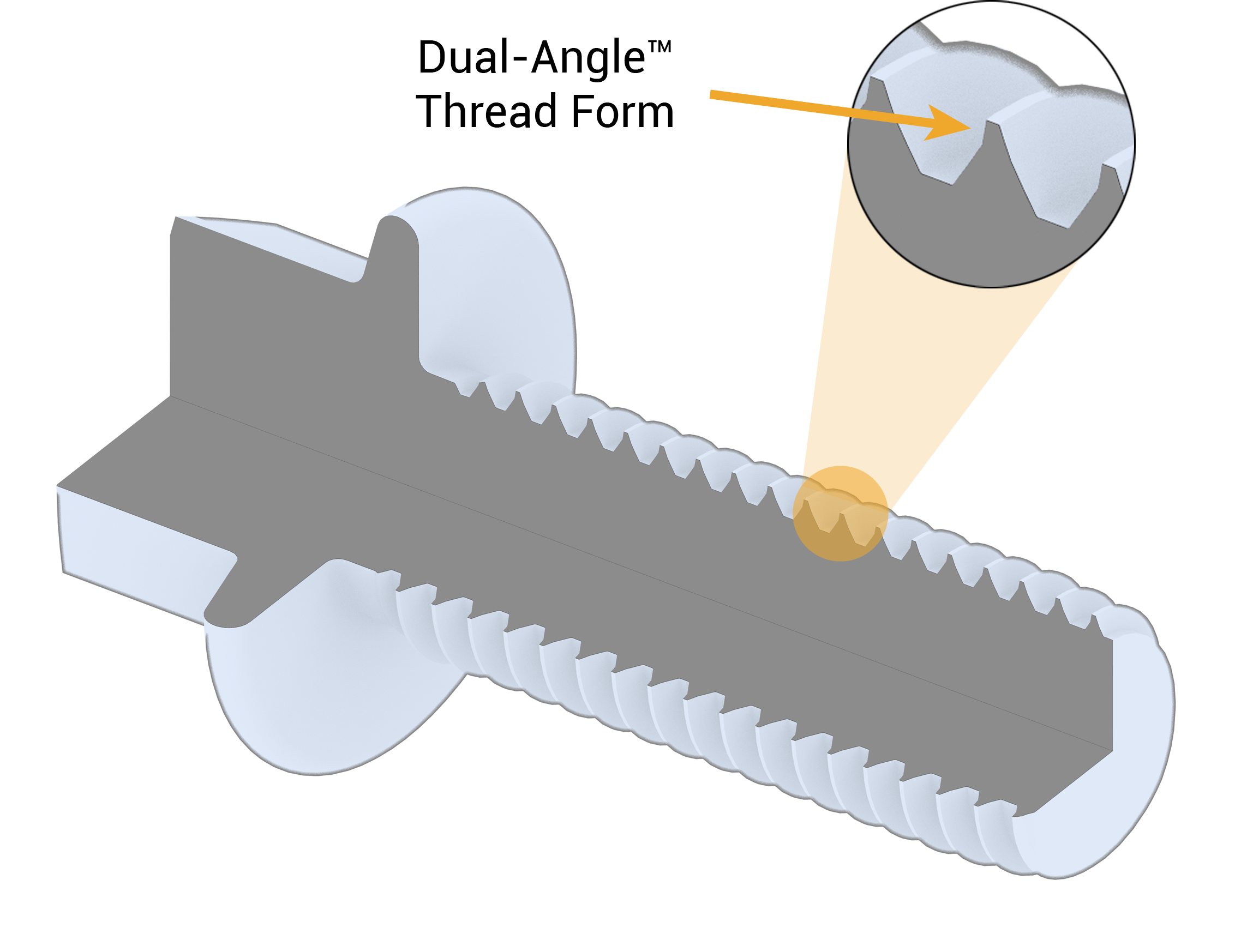

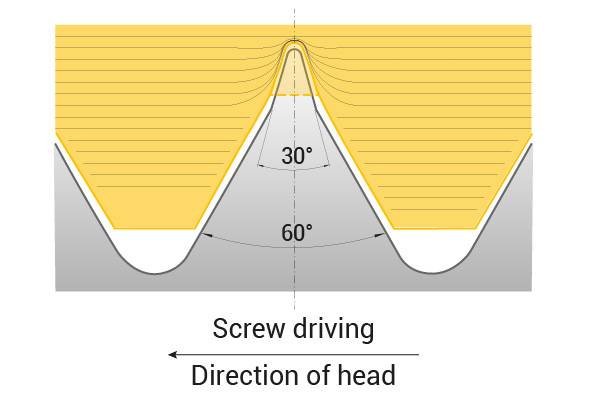

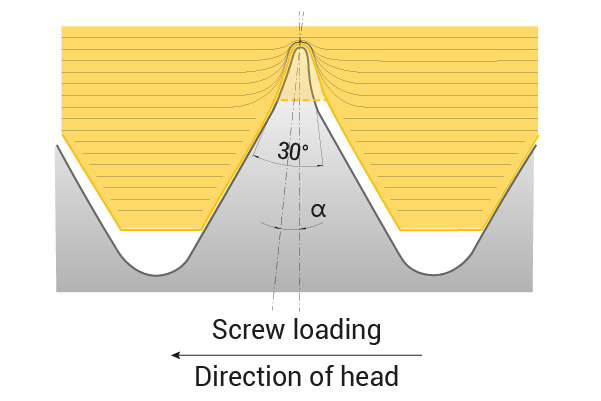

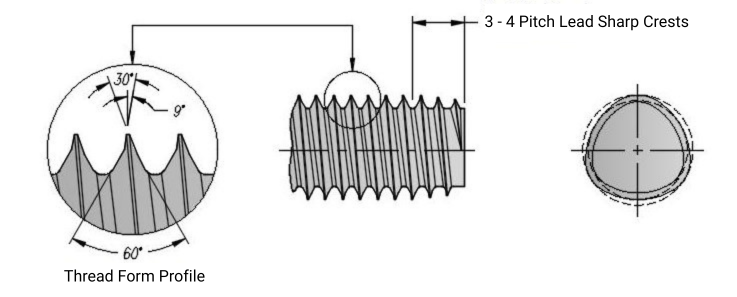

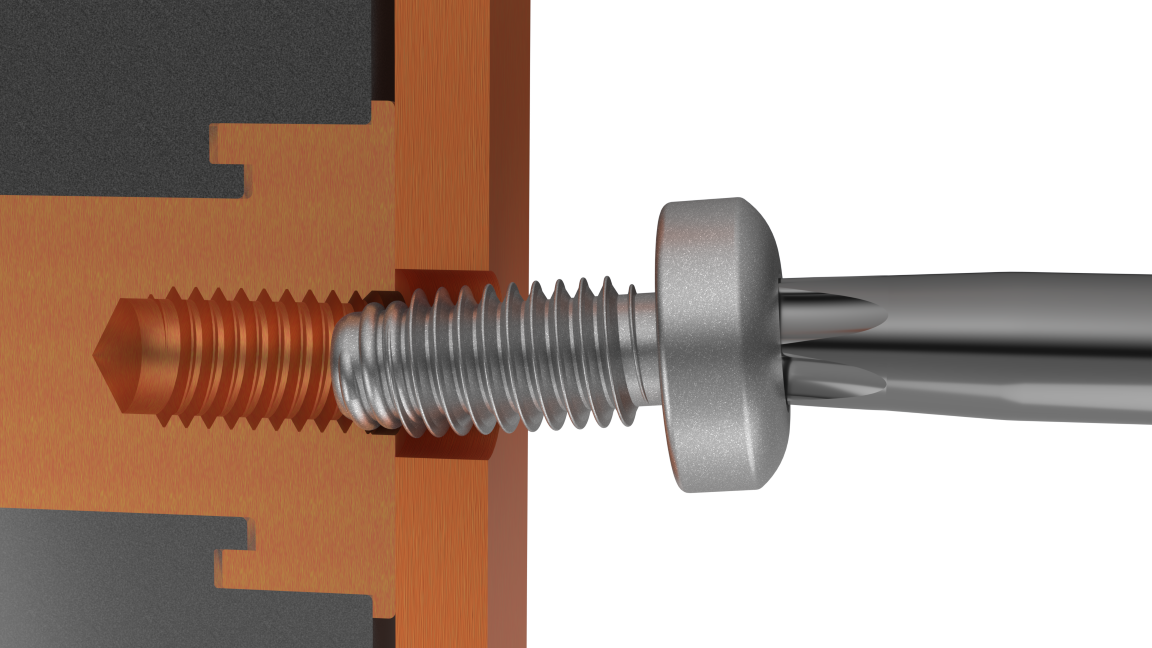

- The innovative Dual-Angle™ thread form provides “live-action” locking over its entire length, regardless of the fastened materials and operating temperatures.

- It interferes with the root of the nut thread, which removes any tolerance.

- To ensure the correct screw performance, the screw’s hardness must be greater than the nut's.

We recommend contacting our technical department to ensure the suitability of POWERLOK® II™ screws for your application.

Benefits

- Immediate and continuous locking action. POWERLOK® II™, being an all-metal locking screw, do not lose their efficiency in high operating temperatures.

- In-place fastening cost reduction by eliminating the need for additional locking elements, such as adhesive patches, locking washer, etc.

- Excellent vibration loosening resistance. POWERLOK® II™screw meets the standards of regulation IFI 524.

- POWERLOK® II™ screws can reach Property Class 10.9 mechanical properties.

- The spring effect maintains clamping force.

- POWERLOK® II™ screws are reusable, the thread design ensures continued locking effectiveness after repeated insertions and removals.

Installation misalignment solution

Misalignment is a common issue in metal pre-tapped hole assembly, leading to problems such as cross-threading, false threading, and component misalignment. Our advanced solution eliminates these risks by ensuring precise alignment from the start, reducing downtime, rework, and scrap for a more efficient assembly process. Learn more

Downloads & Services

Screw design specifications

At CELO, we customize POWERLOK® II™ screws to fit your specific installation requirements. Our screws can be configured with various recess types, thread points, coatings, and cleanliness levels—all based on your specifications.

To enhance assembly efficiency, POWERLOK® II™ screws can also feature a specialized thread point design that prevents cross-threading during insertion. This makes them an ideal choice for semi-automatic and robotic assembly lines, ensuring a smooth installation.

POWERLOK® II™ threads on double-end studs replace inconsistent locking nuts, enabling reliable fastening with standard nuts or Class 2B (6H) tapped holes.

For initial samples, we offer the alternative POWERLOK® screws in stock for immediate delivery.

For further information on the options available, please contact our application engineers.