CELO, global industrial fasteners and screw manufacturer

Double End Studs

When to choose Double End Studs?

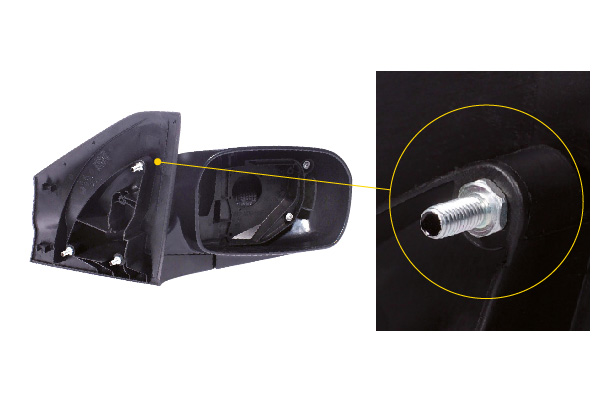

Double end Studs are designed for individual applications where two pieces are to be assembled together. It offers great cost saving possibilities.

How does it work?

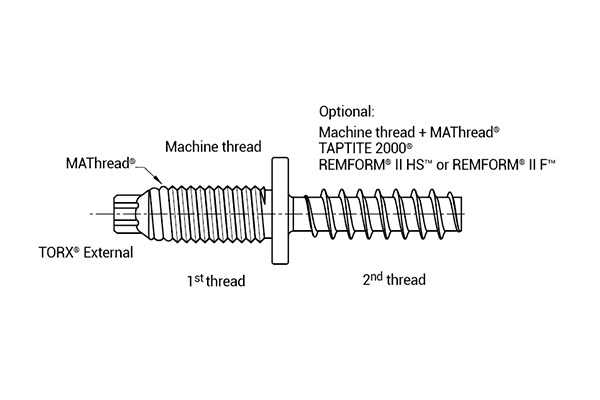

It combines a thread on each end of the shaft, the thread type will depend on the materials to be assembled and the application requirements:

Part A: Machine thread will be installed into a nut. In this case MAThread® point will allow a rapid thread engagement and avoid cross-threading problems.

Double end Studs can be driven by various methods, being variants of TORX® recess the most popular solution:

- TORX® STEM

- TORX PLUS® STEM

- TORX PLUS® Maxx

Part B: Depending on each specific application, different thread design can be considered:

- Assembly of plastic parts: REMFORM® II HS™

- Assembly of light alloy parts (Zamak, Aluminum,…) REMFORM® II F™ or TAPTITE 2000®

- Assembly into a nut: MACHINE thread + MAThread® point.

Benefits

Double End Studs enhance the assembly of two parts as it has two sets of threads in one unique part. Its functionality reduces the assembly system and provides great opportunities for assembly cost saving, avoiding alternative solutions that represent more elements and the design of more complicated parts.

To maximize cost savings, it’s important that Double end Studs are considered at the initial phase of the assembly project, when the design of the components to assemble takes place.

Downloads & Services

Screw design specifications

The design of Double End Studs depends on each customer's specific requirements.

This product is produced under special demand to suit your exact requirements.

For further information, please contact our application engineers.