CELO, global industrial fasteners and screw manufacturer

PlasTORX® overmolding stud

When to choose PlasTORX® stud?

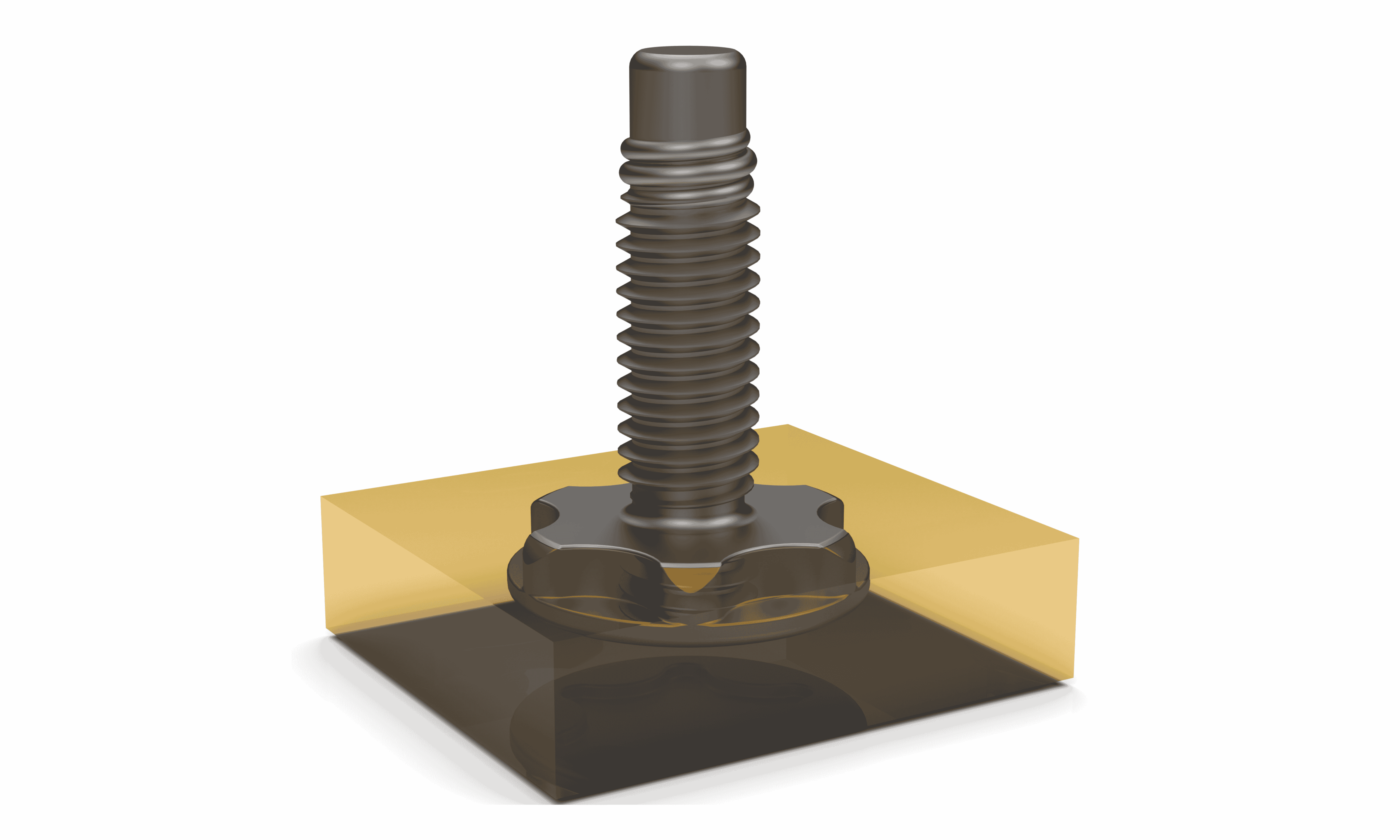

PlasTORX® overmolding studs are an excellent choice for applications in which the stud has to be molded into plastic, offering a reliable alternative to other fasteners assemblies. PlasTORX® studs provide exceptionally high resistance to rotation and pull-out, ensuring a secure fit even in thermoplastics susceptible to cracking or breaking.

As a proven solution in insert molding applications, PlasTORX® studs are widely used in industries such as electronics, automotive, and other sectors where insert molding is demanded.

How does it work?

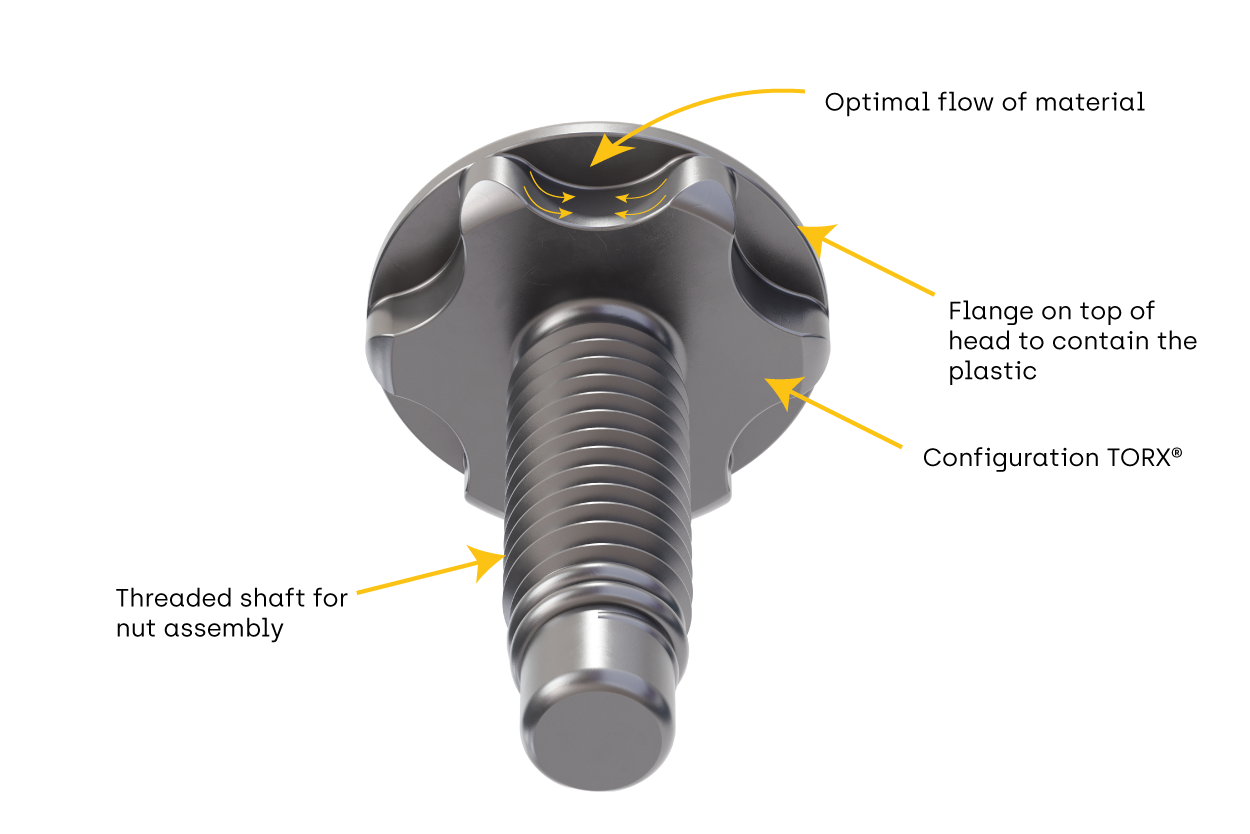

PlasTORX® overmolding studs are designed to be molded directly into plastic applications, which increases assembly efficiency. The stud is inserted easily into the mold, plastic flows through the hex-lobular TORX® configuration providing maximum resistance to rotation and pull-out.

Benefits

- Hex-lobular TORX® configuration provides deep lobe engagement, resulting in:

- Increased torsional resistance for greater durability.

- Improved pull-out resistance, ensuring a secure fit.

- Reduced stress risers, minimizing the chance of damage to the material.

- Ideal for use in materials prone to cracking, thanks to their design that applies less stress during installation.

- Engineered to be molded directly into plastic components, enabling the installation of multiple fasteners simultaneously:

- Reduced assembly time for greater efficiency.

- Fewer part numbers, its standardized head design simplifies inventory and lowers associated costs.

- Lower overall production costs.

Downloads & Services

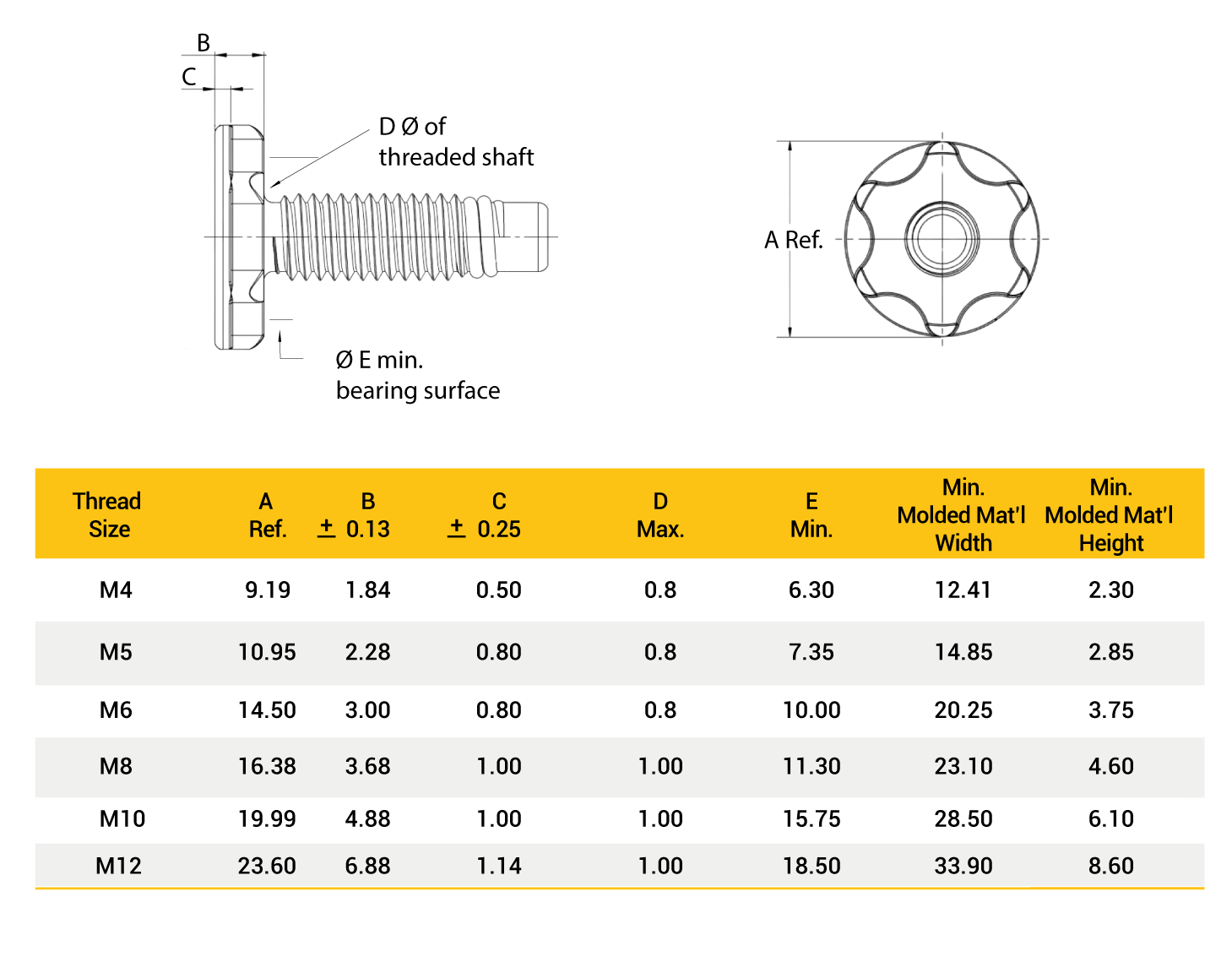

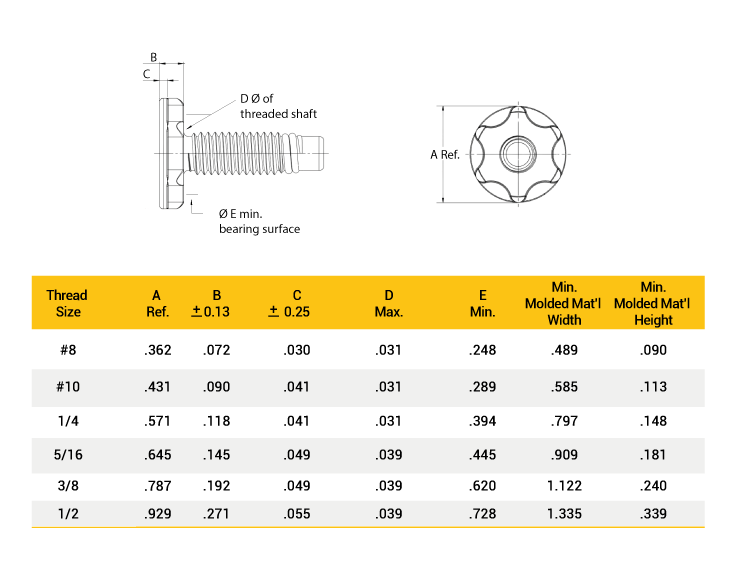

Screw design specifications

We produce PlasTORX® studs on special demand to fit your exact requirements. Diameters range from M4 to M12 (#8 to ½”) and lengths as per customer design.

- We recommend to add MAThread® point to the threaded shaft to prevent cross-threading or blocking problems during nut assembly.

- Optical sorting is recommended to ensure smooth assembly.