CELO, global industrial fasteners and screw manufacturer

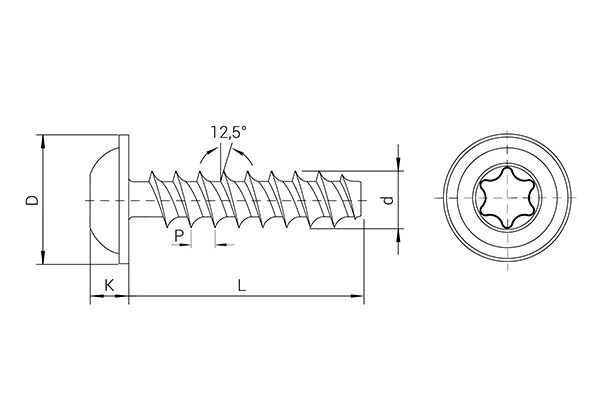

REMFORM® Zinc plated screw, Pan head flange TORX®

The most efficient solution for plastic assemblies with high mechanical requirements

Product overview

REMFORM® thread-forming screws offer a more resistant, secure and ergonomic assembly, while offering great savings on in-place fastening costs.

Unique asymmetric thread form is the main feature of REMFORM® screws and provides important benefits: less radial deformation on the plastic reduces risk of boss bursting, very low thread forming torque values offers ergonomic assembly, strong pull-out resistance, higher breaking torque which allows for higher assembly torque, and high resistance to vibration loosening and stripping.

Apart from the references available in stock, we produce customised screws to fit your exact requirements.

List of references

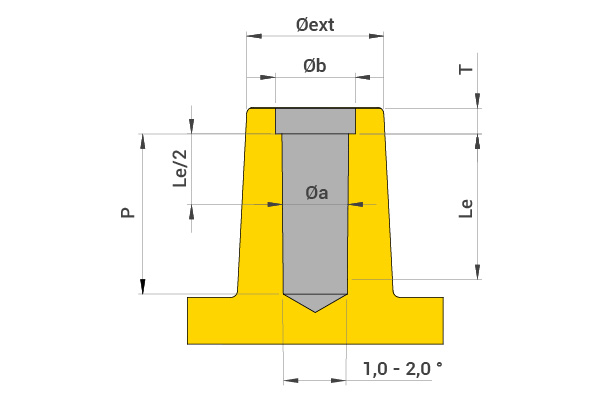

Hole parameters calculator

Applications

Do you have any questions about this product?

Request more info