CELO, global industrial fasteners and screw manufacturer

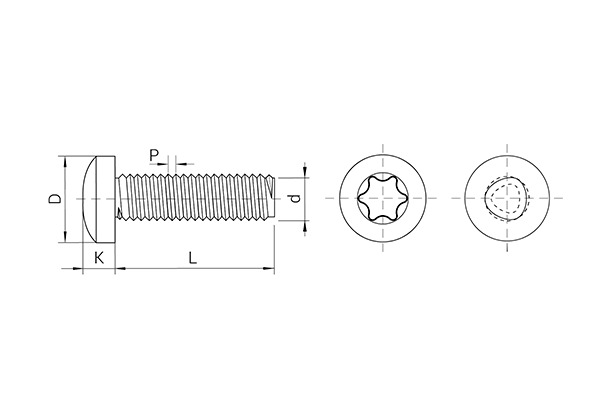

TAPTITE 2000® Zinc plated screw, Pan head TORX®, CORFLEX® N™

TRILOBULAR® TAPTITE 2000® zinc plated screws, the optimal thread rolling screw for light alloy assemblies.

Product overview

TAPTITE 2000® high performance thread rolling screws offer many opportunities to reduce your in-place fastening costs, avoiding tapping operations and providing excellent mechanical properties. The special design improves thread forming process and strengthens the assembly into holes drilled, punched or cast in aluminium and light alloys.

Apart from the references available in stock, we produce customised screws to fit your exact requirements.

List of references

Filters

Screw diameter (mm)

Close

3.0

4.0

5.0

6.0

Screw length L (mm)

Close

6

8

12

16

10

Head diameter D (mm)

Close

6.00

8.00

10.00

12.00

Recess

Close

TORX® T10

TORX® T20

TORX® T25

TORX® T30

Reference

36NT85T

38NT85T

312NT85T

316NT85T

48NT85T

410NT85T

412NT85T

416NT85T

510NT85T

512NT85T

612NT85T

Screw diameter (mm)

3.0

3.0

3.0

3.0

4.0

4.0

4.0

4.0

5.0

5.0

6.0

Screw length L (mm)

6

8

12

16

8

10

12

16

10

12

12

Head diameter D (mm)

6.00

6.00

6.00

6.00

8.00

8.00

8.00

8.00

10.00

10.00

12.00

Recess

TORX® T10

TORX® T10

TORX® T10

TORX® T10

TORX® T20

TORX® T20

TORX® T20

TORX® T20

TORX® T25

TORX® T25

TORX® T30

11 / 11 references are shown

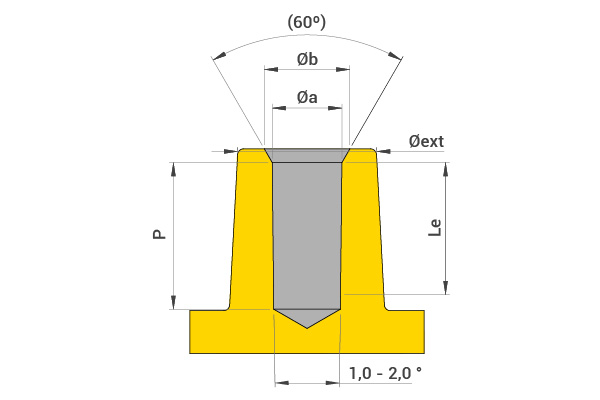

Hole parameters calculator

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the pilot hole diameter. The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.

Go to Design Guidelines

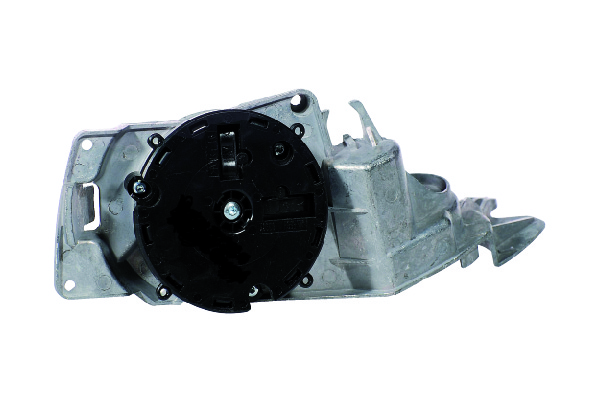

Applications

TAPTITE 2000® screws have been specially designed for the assembly of steel and light alloys in: Components that require a low threading torque. Structural components that require a high pull-out resistance. Components with high tightness requirements.

Do you have any questions about this product?

Request more info