CELO, global industrial fasteners and screw manufacturer

MAThread® screw

When to choose MAThread® screw?

MAThread® point is the solution to cross-threading problems during assembly processes. Machine screws with MAThread® point provides great cost saving opportunities by reducing screw insertion time and eliminating costs derived from downtime, rework and scrap associated to cross-threading.

MAThread® and MATpoint® are registered in product standards of many automotive OEMs including General Motors, Volkswagen, Daimler-Benz and their suppliers.

In addition to automotive industry, manufacturers in electronics, household appliances, telecom and electric sectors are using MAThread® to eliminate assembly problems and lower costs in those highly competitive industries.

How does it work?

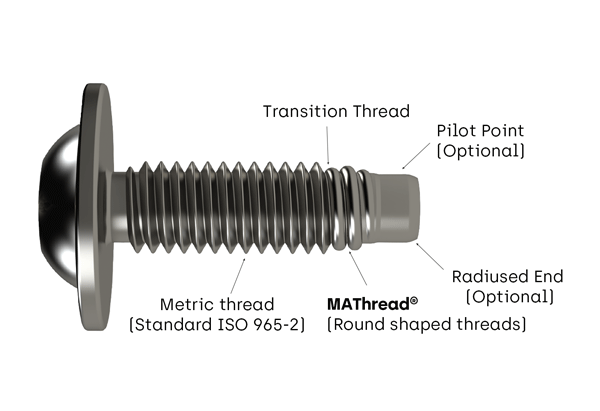

Round shape of MAThread® point aligns the screw to fit the nut member. MAThread® point engages with optimum interference in the nut to straighten the screw up to 15°.

1. There’s misalignment of the MAThread® and the nut member.

2. MAThread® point aligns the screw to fit into nut memeber. It eliminates the risk of cross-threading.

3. Threads drive normally into the nut eliminating the risk of downtime and rework.

MAThread® point screws and its different variants are recommended for assemblies into:

- Nuts, tapped holes and inserts in full automated assembly lines.

- Applications susceptible to cross-threading problems.

Benefits

- Prevents cross-threading and blocking problems.

- Reduces the total cost of assembly:

- MAThread® point allows an easy and rapid insertion without reducing the installation speed.

- Eliminates the cost caused by failures, rework, scrap and downtime associated to cross-threading.

- MAThread® performance is unaffected by installation speed.

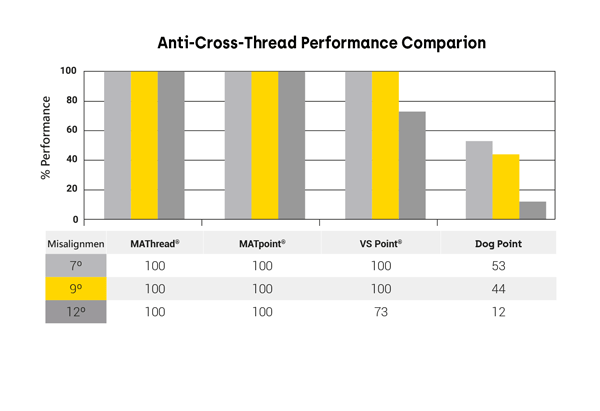

- MAThread® point is the best alternative to the standard Dog Point. In comparison with the standard Dog Point, MAThread® achieves 100% success in alignment.

Screw design specifications

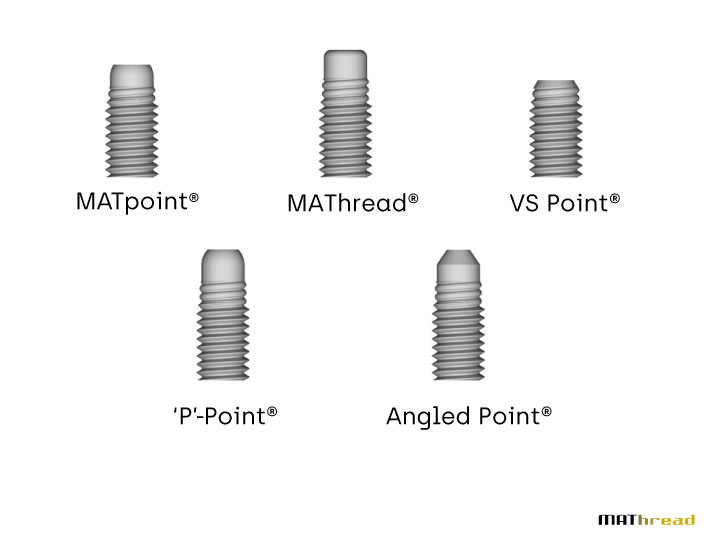

We produce MAThread® screws on special demand to fit your exact requirements. There are different point designs depending on the application requirements:

'P' Point MAThread® for applications in which point length is not a problem.

MATpoint® is compatible with most of the applications, it absorbs misalignments up to 12º.

VS (Very Short) MATpoint® is ideal for application with limited length of engagement, it absorbs misalignments up to 7º.

For further information on options available and hole configuration, please contact our application engineers.