CELO, global industrial fasteners and screw manufacturer

REMFORM® II F™ screw for light alloys

When to choose REMFORM® II F™ screw?

REMFORM® II F™ thread forming screws are specially designed for the assembly of Magnesium, Aluminum light alloy and other non-ferrous materials including copper, brass, etc.

REMFORM® II F™ screws are recommended for:

- Magnesium elements with drilled, injected or punched holes.

- Aluminum profiles with open holes.

How does it work?

- REMFORM® II F™ screws form their own threads into untapped holes.

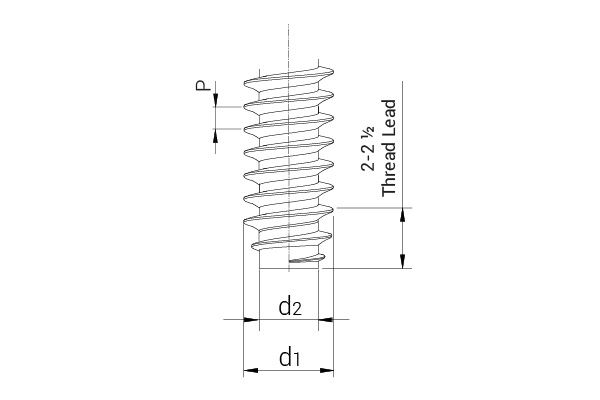

- The smaller pitch of REMFORM® II F™ screws increases pull-out and vibrational loosening resistance.

- The lead threads facilitate alignment into the hole, avoiding the possibility of blockage.

- In applications on Magnesium, the hole diameter may have a wide spread. The design of REMFORM® II F™ screws allows absorbing this variability in the diameter and ensures thread forming in pilot holes with wide tolerance.

Benefits

- Great cost saving opportunities by reducing the operations associated to metric screws.

- Thread design ensures thread forming in pilot holes with a wide tolerance, avoiding blockage and stripping problems.

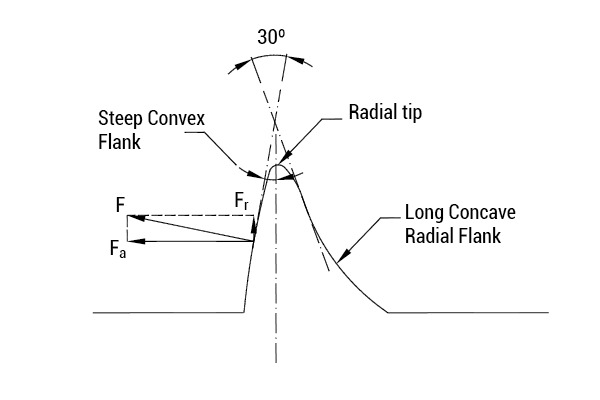

- Less radial deformation of the housing during thread forming on low ductility materials.

- Low thread forming torque, which provides a more ergonomic assembly.

- High stripping resistance of the assemblies.

- Greater thread engagement, allowing for its use in shallow holes and ensuring greater clamping transmission and pull-out resistance.

Downloads & Services

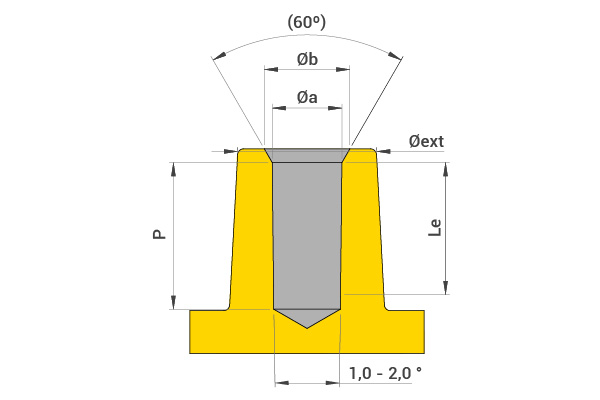

Screw design specifications

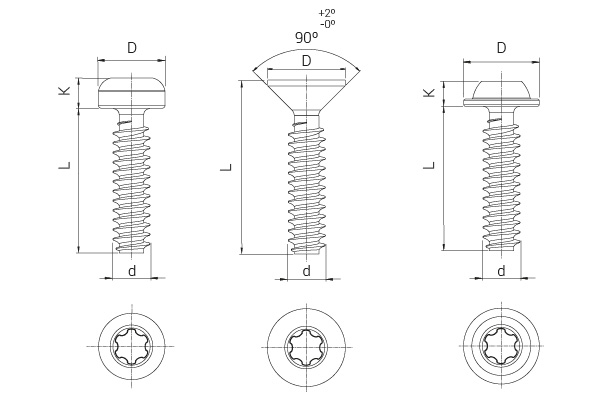

We produce customized REMFORM® II F™ screws to fit your exact requirements. To improve their functionality, REMFORM® II F™ screws can be produced under different head designs, recess, dimensions and coating configuration.

Additionally, we offer a wide range of REMFORM® II F™ screws in stock for immediate delivery.

For further information on the options available, please contact our application engineers.

Pilot hole diameter guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the pilot hole configuration.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.