CELO, global industrial fasteners and screw manufacturer

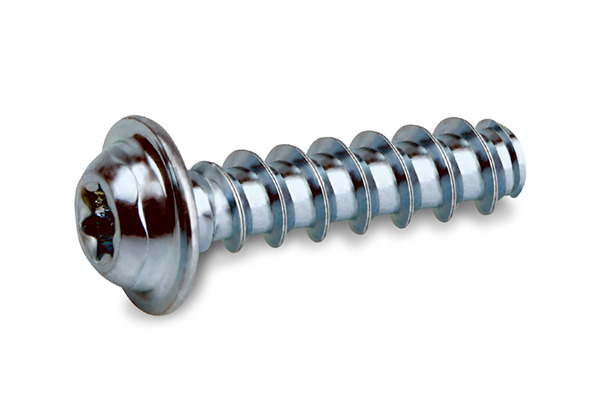

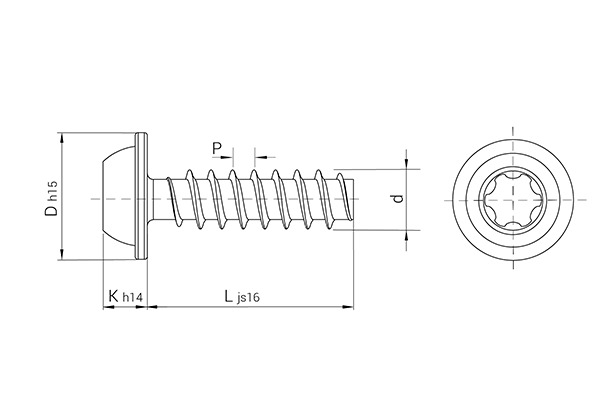

REMFORM® II HS™ Zinc plated screw, Pan head flange TORX PLUS® AUTOSERT®

The best in its class for highly demanding plastic assemblies.

Product overview

REMFORM® II HS™ (High Strength) screws have been developed for the direct assembly of thermoplastics in applications with high mechanical requirements.

The improved thread design results in a more resistant, safe and optimized assembly of fiber reinforced thermoplastics, offering high clamping force, pull-out and vibration loosening resistance.

Apart from the references available in stock, we produce customised screws to fit your exact requirements.

List of references

Filters

Screw diameter (mm)

Close

2.0

2.5

3.0

3.5

4.0

5.0

6.0

Screw length L (mm)

Close

8

10

12

16

20

30

Head diameter D (mm)

Close

4.30

5.30

6.30

7.30

8.30

10.50

12.50

Recess

Close

TORX PLUS® AUTOSERT® 6 IP

TORX PLUS® AUTOSERT® 8 IP

TORX PLUS® AUTOSERT® 10 IP

TORX PLUS® AUTOSERT® 15 IP

TORX PLUS® AUTOSERT® 20 IP

TORX PLUS® AUTOSERT® 25 IP

TORX PLUS® AUTOSERT® 30 IP

Reference

28HS87PA

258HS87PA

38HS87PA

310HS87PA

312HS87PA

3512HS87PA

412HS87PA

416HS87PA

420HS87PA

520HS87PA

620HS87PA

630HS87PA

Screw diameter (mm)

2.0

2.5

3.0

3.0

3.0

3.5

4.0

4.0

4.0

5.0

6.0

6.0

Screw length L (mm)

8

8

8

10

12

12

12

16

20

20

20

30

Head diameter D (mm)

4.30

5.30

6.30

6.30

6.30

7.30

8.30

8.30

8.30

10.50

12.50

12.50

Recess

TORX PLUS® AUTOSERT® 6 IP

TORX PLUS® AUTOSERT® 8 IP

TORX PLUS® AUTOSERT® 10 IP

TORX PLUS® AUTOSERT® 10 IP

TORX PLUS® AUTOSERT® 10 IP

TORX PLUS® AUTOSERT® 15 IP

TORX PLUS® AUTOSERT® 20 IP

TORX PLUS® AUTOSERT® 20 IP

TORX PLUS® AUTOSERT® 20 IP

TORX PLUS® AUTOSERT® 25 IP

TORX PLUS® AUTOSERT® 30 IP

TORX PLUS® AUTOSERT® 30 IP

12 / 12 references are shown

Hole parameters calculator

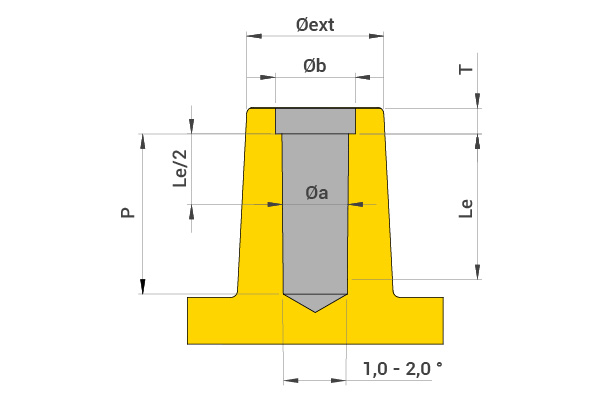

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design. The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.

Go to Design Guidelines

Applications

REMFORM® II HS™ screws are recommended for assemblies on high strength or fiber-reinforced materials that require: High assembly torque, either with hard plastics or very deep assemblies. High clamping force. High pull-out resistance. High resistance to vibration loosening.

Do you have any questions about this product?

Request more info