CELO, global industrial fasteners and screw manufacturer

CELOspArk® screw

When to choose CELOspArk® screw?

CELOspArk® screw is the last evolution of our CELOPLAST screw. The improved 30º thread design solves the problem of boss bursting and provides greater safety in the assembly process into ductile plastics.

The design of CELOspArk® screws meet the standards of a large number of electric material, electronics and automotive manufacturers (i.e. VW 603 62).

How does it work?

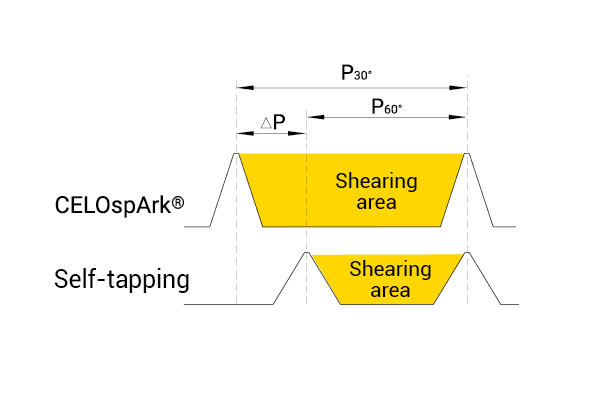

When compared CELOspArk® to self-tapping screws (ISO 1478), the larger thread pitch and thread height of CELOspArk® screw results in bigger shearing zone, providing a more resistant nut member and, consequently, an increase in pull-out and stripping resistance.

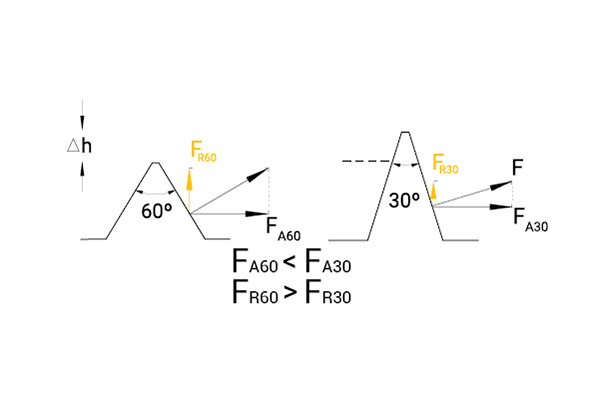

If we carry out a resolution of resultant forces, 30º thread angle provides a 50% reduction of radial tension (Fr) when compared to self-tapping screws (60º).

The technical benefits of CELOspArk® screws provide a more resistant assembly, greater safety during threading and lower costs of assembly.

Benefits

- 30º thread design generates less radial tension on plastic reducing the problem of boss bursting.

- Allows for bosses with smaller diameter, reducing the cost of the assembly.

- Lower thread forming torque for a more ergonomic assembly.

- More resistant to pull-out and vibrational loosening.

- Higher stripping resistance.

- Quick alignment of the screw before screwing in, thus reducing assembly time.

- Screws can be reused with a reduced risk of stripping.

Downloads & Services

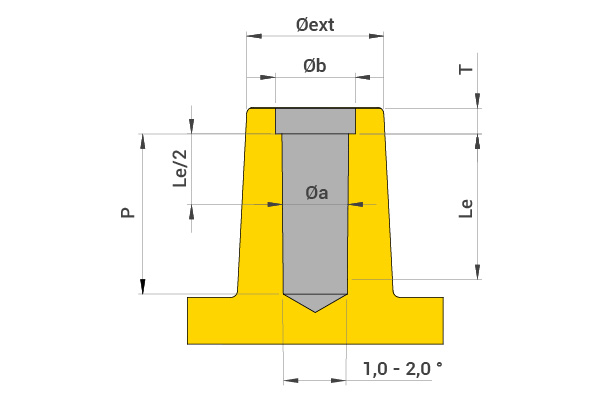

Screw design specifications

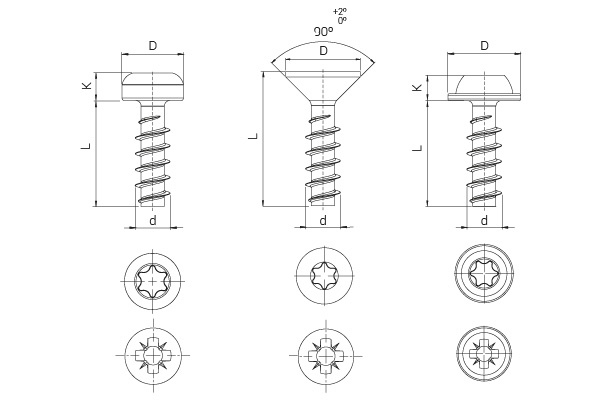

We produce customized CELOspArk® screws to fit your exact requirements. To improve their functionality, CELOspArk® screws can be produced under different head designs, recess, dimensions and coating configuration.

Additionally, we offer a wide range of CELOspArk® screws in stock for immediate delivery.

For further information on the options available, please contact our application engineers.

Products in stock

SP81P

CELOspArk® Zinc plated screw, Pan head TORX PLUS®

Go to the product

SP81T

CELOspArk® Zinc plated screw, Pan head TORX®

Go to the product

SP81Z

CELOspArk® Zinc plated screw, Pan head POZI

Go to the product

SP87P

CELOspArk® Zinc plated screw, Pan head flange TORX PLUS®

Go to the product

SP87T

CELOspArk® Zinc plated screw, Pan head flange TORX®

Go to the product

SP87Z

CELOspArk® Zinc plated screw, Pan head flange POZI

Go to the product

SP82T

CELOspArk® Zinc plated screw, Countersunk head TORX®

Go to the product

SP82Z

CELOspArk® Zinc plated screw, Countersunk head POZI

Go to the productBoss Design Guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the boss design.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.