CELO, global industrial fasteners and screw manufacturer

TAPTITE 2000® screws

When to choose TAPTITE 2000® screw?

TAPTITE 2000® high performance thread rolling TRILOBULAR® screws offer many opportunities to reduce your in-place fastening costs, avoiding tapping operations and provides excellent mechanical properties.

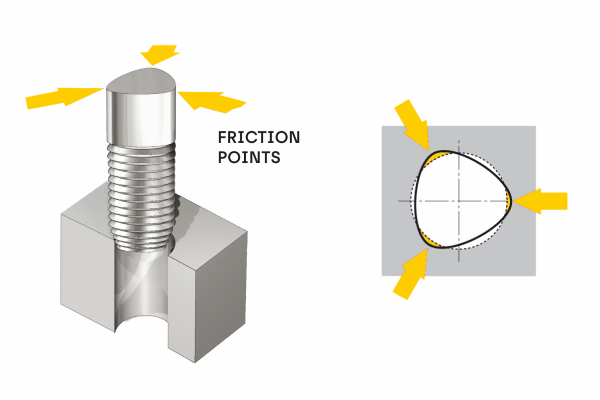

The special TRILOBULAR® design improves the thread forming process and strengthens the assembly into holes drilled, punched or cast in steel, aluminum or light alloys.

TAPTITE 2000® screws have been specially designed for the assembly of steel and light alloys in:

- Components that require a low threading torque.

- Structural components that require a high pull-out resistance.

- Components with high tightness requirements.

How does it work?

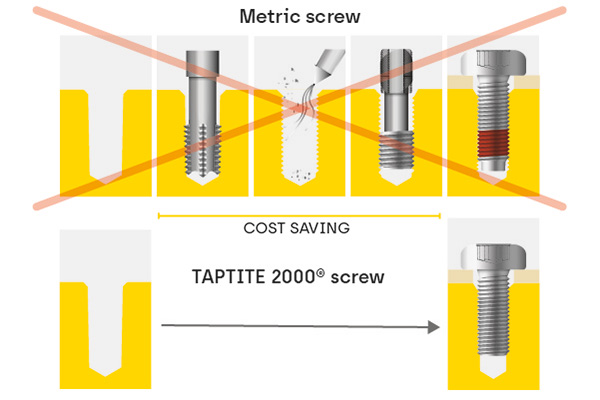

Only 15% of all assembly costs corresponds to the screws. TAPTITE 2000® screws are specially designed to reduce the remaining 85%.

- TAPTITE 2000® screws create a resistant and uniform thread into untapped holes with the tolerance of a machine thread.

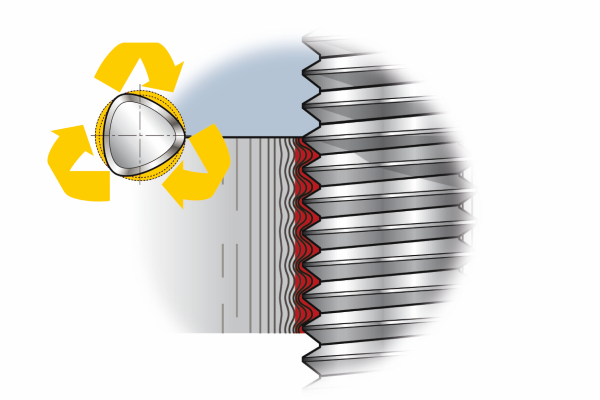

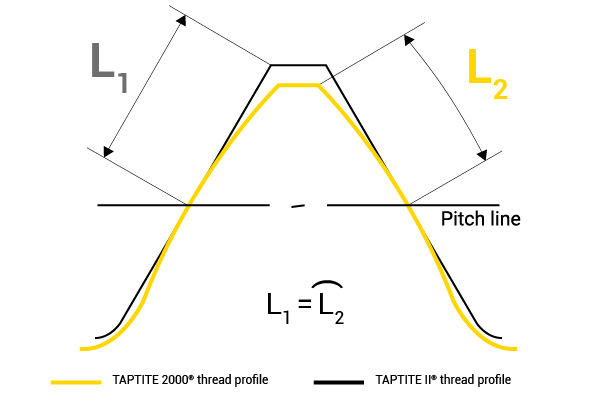

- Radius Profile™ thread reduced thread forming torque, resulting in higher pull-out and vibration loosening resistance.

- Progressive point allows for excellent axial alignment, requiring very low end load.

- Thread forming by material lamination avoids chips creation.

- Material displaced during threading flows to fill the space between the lobes and eliminates the tolerance between the screw and the nut member.

Benefits

- It reduces assemblies’ overall costs. It eliminates the need to pre-tap and all the associated costs when using machine screws. See more

- More ergonomic assemblies. Its excellent axial alignment provides low axial end load to initiate thread forming.

- It eliminates the cross-threading problems associated to screw assemblies into pre-tapped holes.

- Excellent pull-out and vibration loosening resistance.

- It provides a higher clamping force.

- High prevailing torque.

Downloads & Services

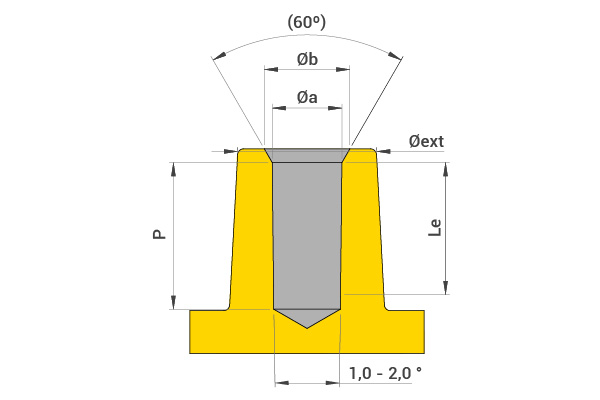

Screw design specifications

We produce customized TAPTITE 2000® screws to fit your exact requirements. To improve their functionality, TAPTITE 2000® screws can be produced with different head types, recess, dimensions and coating configuration.

TAPTITE 2000® thread can be adapted to your assembly needs:

- TAPTITE 2000® CA™ is specially recommended for assemblies where clearance and pilot holes are not aligned.

- TAPTITE 2000® SP™ specially recommended to maximize full thread engagement in shallow blind holes.

- TAPTITE 2000® CORFLEX® N™ exclusive for aluminum and light alloy assemblies, improves bending and resistance in heavy load cycles.

For further information on options available, please contact our application engineers.

Products in stock

NT85T

TAPTITE 2000® Zinc plated screw, Pan head TORX®, CORFLEX® N™

Go to the product

T285PA

TAPTITE 2000® Zinc plated screw, Pan head TORX PLUS® AUTOSERT®

Go to the product

T251H

TAPTITE 2000® screw, Pan head PHILLIPS (inch)

Go to the product

NT85PA

TAPTITE 2000® Zinc plated screw, Pan head TORX PLUS® AUTOSERT®, CORFLEX® N™

Go to the productPilot hole diameter guidelines

In order to ensure a safe installation and stable clamping force, it's relevant to pay attention to the pilot hole diameter.

The recommended dimensions for core hole diameter and length of engagement are available at Design Guidelines.